10 月 . 10, 2024 14:19 Back to list

titanium dioxide blr-895 for automotive oem coatings and refinishing coatings manufactured by chloride process

The Role of Titanium Dioxide BLR-895 in Automotive OEM Coatings and Refinishing Coatings

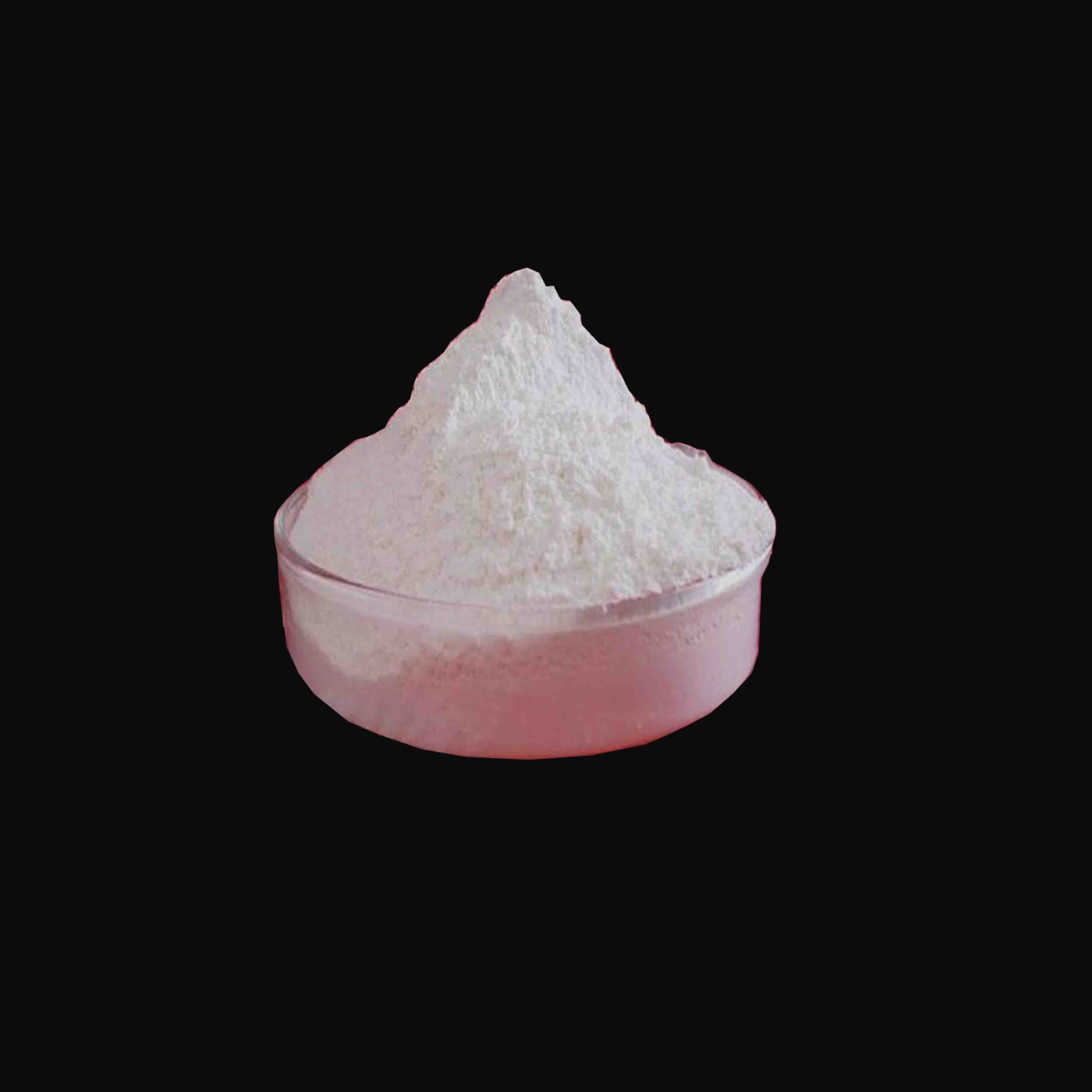

Titanium dioxide (TiO2) is a widely used pigment in the coatings industry, particularly in automotive OEM (Original Equipment Manufacturer) and refinishing applications. Among various grades available, Titanium Dioxide BLR-895, produced by the chloride process, has emerged as a leading choice due to its unique properties that enhance the durability, aesthetics, and performance of automotive coatings.

Understanding Titanium Dioxide and Its Benefits

Titanium dioxide is celebrated for its excellent opacity, brightness, and UV resistance. These attributes make it a preferred pigment for a diverse range of coatings. The efficacy of TiO2 in automotive coatings lies in its ability to provide high hiding power, ensuring that color is not only vivid but also enduring, even under harsh environmental conditions. This is crucial for vehicles, which are subjected to sunlight, rain, and pollutants.

Titanium Dioxide BLR-895 is particularly suited for automotive applications due to its high purity and specific particle size distribution, which are critical in achieving the desired gloss and color retention in both OEM and refinishing coatings.

The Chloride Process Advantage

The production of Titanium Dioxide BLR-895 via the chloride process offers several advantages over the traditional sulfate process. The chloride process yields a purer product, with a lower level of impurities that can adversely affect the performance of coatings. This increased purity translates into better stability and consistency in the final coatings, which is essential for automotive applications where precision and reliability are paramount.

Furthermore, the chloride process allows for better control over the particle size and morphology of the titanium dioxide. These characteristics are significant as they directly influence the performance attributes such as tinting strength, dispersion, and lightfastness of the coatings. This means that manufacturers can tailor their products with a high degree of precision, resulting in superior automotive finishes.

titanium dioxide blr-895 for automotive oem coatings and refinishing coatings manufactured by chloride process

Applications in OEM Coatings

In automotive OEM coatings, Titanium Dioxide BLR-895 plays a pivotal role in both basecoats and clearcoats. The brightness and hiding power of Titanium Dioxide ensure that manufacturers can achieve vibrant colors that stand out while providing the necessary coverage. The high durability of BLR-895 contributes to long-lasting finishes that resist fading, chalking, and other forms of degradation caused by environmental exposure.

Moreover, BLR-895's compatibility with modern resin systems used in automotive coatings allows for easy formulation adjustment, making it an integral part of the product development process. Its performance enhancements not only improve the visual appeal of vehicles but also contribute to their overall longevity, reducing the frequency of refinishing.

Refinishing Coatings A Critical Component

The refinishing segment is equally important, as it allows for the restoration of vehicles that may have suffered from wear and tear or damage. Here, Titanium Dioxide BLR-895 continues to shine. The ease of application, combined with the excellent performance characteristics of the pigment, leads to a finish that is both aesthetically pleasing and durable. The enhanced resistance to yellowing and fading ensures that refinished cars maintain their appeal over time.

Furthermore, as environmental regulations become increasingly stringent, the use of high-quality materials like BLR-895 not only meets these standards but often exceeds them. Manufacturers seeking to produce eco-friendly coatings benefit from the efficient performance of TiO2, helping them to reduce their overall material usage while still delivering exceptional results.

Conclusion

In conclusion, Titanium Dioxide BLR-895 represents a cornerstone of modern automotive OEM and refinishing coatings. The purity and performance advantages provided by the chloride process make it a superior choice, ensuring that vehicles not only look good but also withstand the test of time. As the automotive industry continues to innovate, the role of high-quality pigments like Titanium Dioxide remains pivotal in helping manufacturers meet the demands of both consumers and regulatory bodies. The adoption of BLR-895 is not just a trend; it's a testament to the ongoing quest for excellence in automotive finishing.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025