10 月 . 06, 2024 01:48 Back to list

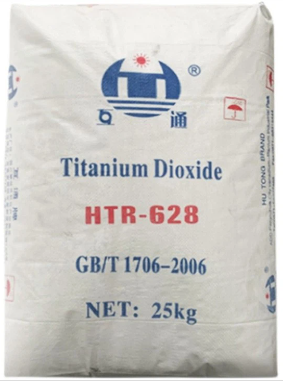

titanium dioxide in plastics supplier

The Role of Titanium Dioxide in Plastics A Comprehensive Overview

Titanium dioxide (TiO₂) is a white pigment that has garnered significant attention in various industries due to its remarkable properties. One of its most critical applications is in the realm of plastics. As a supplier of titanium dioxide for plastics, understanding its role, benefits, and applications is crucial for maximizing its potential in this versatile material.

What is Titanium Dioxide?

Titanium dioxide is a naturally occurring mineral that is sourced primarily from ilmenite, rutile, and anatase. It is known for its high refractive index, which gives it excellent opacity and brightness. These characteristics make it an ideal pigment for producing vibrant and long-lasting colors in various applications, including paints, coatings, and plastics.

Benefits of Titanium Dioxide in Plastics

1. Enhanced Opacity and Whitness One of the most significant benefits of incorporating titanium dioxide into plastics is its ability to provide superior opacity and whiteness. This is essential for manufacturers aiming for high-quality products that require a bright and uniform finish.

2. UV Protection Titanium dioxide exhibits excellent UV-blocking properties. This makes it particularly valuable for outdoor applications, where plastics are exposed to harmful UV rays that can cause degradation over time. The inclusion of TiO₂ can prolong the life of plastic products by minimizing fading and brittleness.

3. Stability and Durability Plastics infused with titanium dioxide tend to have enhanced durability. TiO₂ is chemically stable, which means it maintains its properties under various environmental conditions. This provides greater resistance to heat, moisture, and chemical exposure.

4. Non-Toxic and Environmental Safety Titanium dioxide is considered non-toxic to humans and the environment when used properly. This aspect is increasingly important in today's market, where consumers and regulatory bodies are more conscious of the materials that go into products.

5. Cost-Effectiveness While there may be initial costs associated with sourcing titanium dioxide, its integration into plastic products often leads to cost savings in the long run. The durability and extended lifespan reduce the need for replacements and repairs, making it a financially sound choice for manufacturers.

titanium dioxide in plastics supplier

Applications of Titanium Dioxide in Plastics

Titanium dioxide is utilized in a wide range of plastic products. Some common applications include

- Packaging Materials TiO₂ is frequently used in the production of plastic packaging materials to create opaque films and containers. This not only helps preserve the contents from light degradation but also improves the aesthetic appeal.

- Automotive and Aerospace Parts In the automotive and aerospace industries, TiO₂ is used to enhance the performance and durability of interior and exterior components. Its UV protection and heat resistance make it ideal for parts subjected to harsh conditions.

- Building and Construction Plastics used in construction applications benefit from titanium dioxide's protective qualities, helping building materials withstand weathering and ensuring lasting structural integrity.

- Consumer Goods Products such as toys, appliances, and household items often incorporate TiO₂ for its aesthetic and protective properties, ensuring they are not only visually appealing but also durable and safe.

Conclusion

As a supplier of titanium dioxide for plastics, it’s important to recognize its versatility and the numerous advantages it offers. From enhancing opacity and UV protection to providing stability and durability, TiO₂ proves to be a valuable additive that meets the evolving needs of various industries. As consumers demand higher quality and environmentally friendly products, the role of titanium dioxide in plastics will only continue to grow, reinforcing its status as an indispensable component in modern manufacturing processes.

In summary, the incorporation of titanium dioxide in plastics not only meets practical needs but also aligns with sustainability goals, establishing it as a key player in the future of material science.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025