10 月 . 10, 2024 17:29 Back to list

titanium dioxide insoluble factory

The Role of Titanium Dioxide in Insulation and Its Factory Production

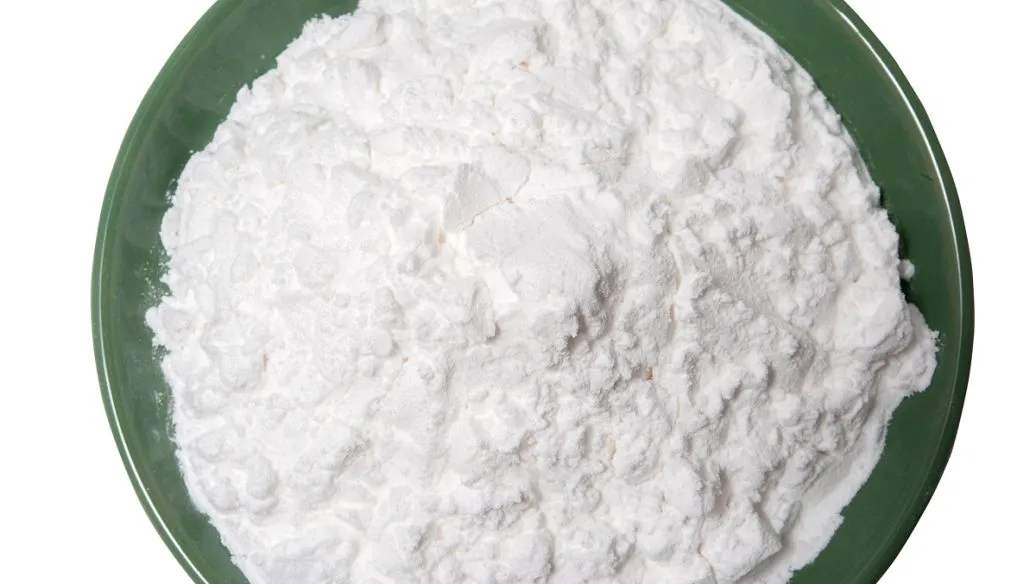

Titanium dioxide (TiO2) is a remarkable compound that has gained immense popularity due to its unique properties. Characterized by its high refractive index, excellent UV light absorption, and pigmentation capabilities, titanium dioxide is commonly used in various applications, ranging from paints and coatings to food and cosmetics. One of the less discussed but significantly important aspects of titanium dioxide is its insoluble form, utilized extensively in the manufacturing sector. This article explores the implications of titanium dioxide’s insolubility and the nuances of its factory production.

The Role of Titanium Dioxide in Insulation and Its Factory Production

In the production process, the creation of insoluble titanium dioxide generally involves two primary methods the sulfate process and the chloride process. The sulfate process uses sulfuric acid, titanium ore, and water to produce a hydrated titanium dioxide, which is then converted into titanium dioxide pigment after calcination. Although this method is well-established, it can lead to environmental concerns due to the generation of large amounts of sulfuric wastes.

titanium dioxide insoluble factory

On the other hand, the chloride process is considered more environmentally friendly. It involves reacting titanium tetrachloride with oxygen to produce titanium dioxide. This method produces a purer and more consistent product with less waste, owing to its closed-loop system. As industries increasingly seek sustainable practices, the chloride process is gaining traction, allowing for the rise of cleaner production methods in titanium dioxide factories.

Despite the advantages of titanium dioxide, factories producing this crucial material must navigate various challenges. One of the primary concerns is the potential environmental impact of titanium dioxide production. The dust generated during the manufacture of TiO2, coupled with its particulate nature, poses health risks to workers and environmental hazards. Safety regulations demand that factories implement stringent measures to minimize exposure and emissions. Furthermore, as the world moves towards more sustainable practices, the need for greener production methods and responsible sourcing of raw materials has become critical in the titanium dioxide industry.

The global market for titanium dioxide remains robust, with demand projected to grow significantly in the coming years, driven by expanding applications in construction, automotive, and even new technological advancements. The increasing focus on high-quality, durable materials will further bolster the factory production of titanium dioxide, particularly in its insoluble form. Companies that adapt to changing regulations, innovate manufacturing processes, and emphasize sustainability are poised to thrive in this dynamic landscape.

In conclusion, titanium dioxide's insubstantial properties make it a vital ingredient across various industrial landscapes. Its durability, pigmentation capabilities, and exceptional resistance to weathering give it an edge over other compounds. However, the production process in factories must evolve to address environmental concerns. As we look forward to the future of titanium dioxide, it is essential to embrace sustainable practices while meeting the growing demand for this versatile compound. The journey of titanium dioxide, particularly in its insoluble form, is a testament to the intersection of chemistry, industry, and sustainability—a narrative that continues to unfold as technology and environmental consciousness evolve.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025