10 月 . 07, 2024 10:58 Back to list

titanium dioxide used in rubber supplier

Titanium Dioxide in Rubber A Key Ingredient and Its Suppliers

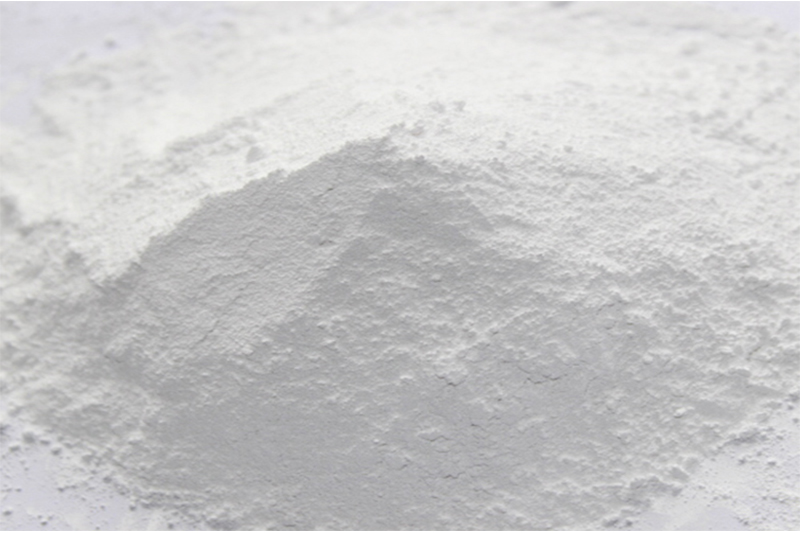

Titanium dioxide (TiO2) has established itself as an essential ingredient in various industries, including coatings, plastics, and notably, rubber. The addition of titanium dioxide to rubber compounds not only enhances the physical properties of the final product but also contributes significantly to performance characteristics such as UV resistance, opacity, and brightness. As the global demand for high-quality rubber products increases, so does the need for reliable titanium dioxide suppliers.

The Role of Titanium Dioxide in Rubber

Titanium dioxide serves multiple purposes in rubber manufacturing. One of its primary functions is as a pigment. The high refractive index and excellent light-scattering properties of TiO2 allow manufacturers to produce rubber products that are opaque and have a bright white appearance. This is particularly valuable in tire manufacturing and other applications where aesthetics and visibility are critical.

Moreover, titanium dioxide improves the durability and UV resistance of rubber products. The addition of this compound can enhance weatherability, making rubber suitable for outdoor applications where exposure to sunlight and harsh environmental conditions is inevitable. This quality is essential for items such as seals, adhesives, and coatings, where longevity and reliability are paramount.

Furthermore, titanium dioxide can enhance the mechanical properties of rubber. By incorporating TiO2, manufacturers can improve tensile strength, abrasion resistance, and overall elasticity. This makes it a favored additive in high-performance rubber formulations used in automotive and industrial applications.

Suppliers of Titanium Dioxide

The global supply chain for titanium dioxide in rubber is diverse and competitive, comprising numerous manufacturers and distributors. Leading suppliers tend to offer a range of TiO2 grades specifically engineered for rubber applications. When choosing a supplier, manufacturers often consider factors such as product quality, consistency, regulatory compliance, and logistics.

titanium dioxide used in rubber supplier

Some prominent titanium dioxide producers include companies like Chemours, Tronox, and Kronos. These companies dominate the market, providing high-quality TiO2 that meets the specific needs of various applications, including rubber. Furthermore, emerging players are also entering the market, focusing on niche segments and innovative formulations of TiO2.

When selecting a supplier, it is crucial to consider the specifications of the titanium dioxide offered. Different grades of TiO2 have varying particle sizes, surface treatments, and properties, all of which can impact the performance of rubber products. Therefore, manufacturers must engage with suppliers who understand the complexities of rubber formulations to ensure optimal results.

Sustainability Considerations

As with many industries, sustainability is becoming an increasingly important consideration in the titanium dioxide supply chain. Rubber manufacturers are starting to prioritize suppliers who adhere to environmentally friendly practices, from the extraction of raw materials to the production processes involved in creating TiO2.

Recycling and the development of bio-based titanium products are gaining traction as part of a broader commitment to sustainability. These advancements can help reduce the environmental footprint of rubber products while maintaining performance standards.

Conclusion

Titanium dioxide plays a critical role in enhancing the performance and aesthetic quality of rubber products. Its applications span a wide range of industries, making it a sought-after material among manufacturers. Suppliers who can provide high-quality TiO2 are essential to the rubber sector, especially as demand for stronger, more durable, and environmentally friendly products continues to grow.

As manufacturers navigate through the complexities of sourcing titanium dioxide, they must prioritize suppliers who not only offer superior products but also align with sustainability goals. With the ongoing innovations in both titanium dioxide production and rubber formulations, the future looks bright for this indispensable partnership in manufacturing, ensuring that rubber products remain robust, reliable, and ready to meet the challenges of tomorrow.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025