10 月 . 01, 2024 21:55 Back to list

Exploring Different Wholesale Categories for Titanium Dioxide Types

Understanding Wholesale Types of TiO2 A Comprehensive Overview

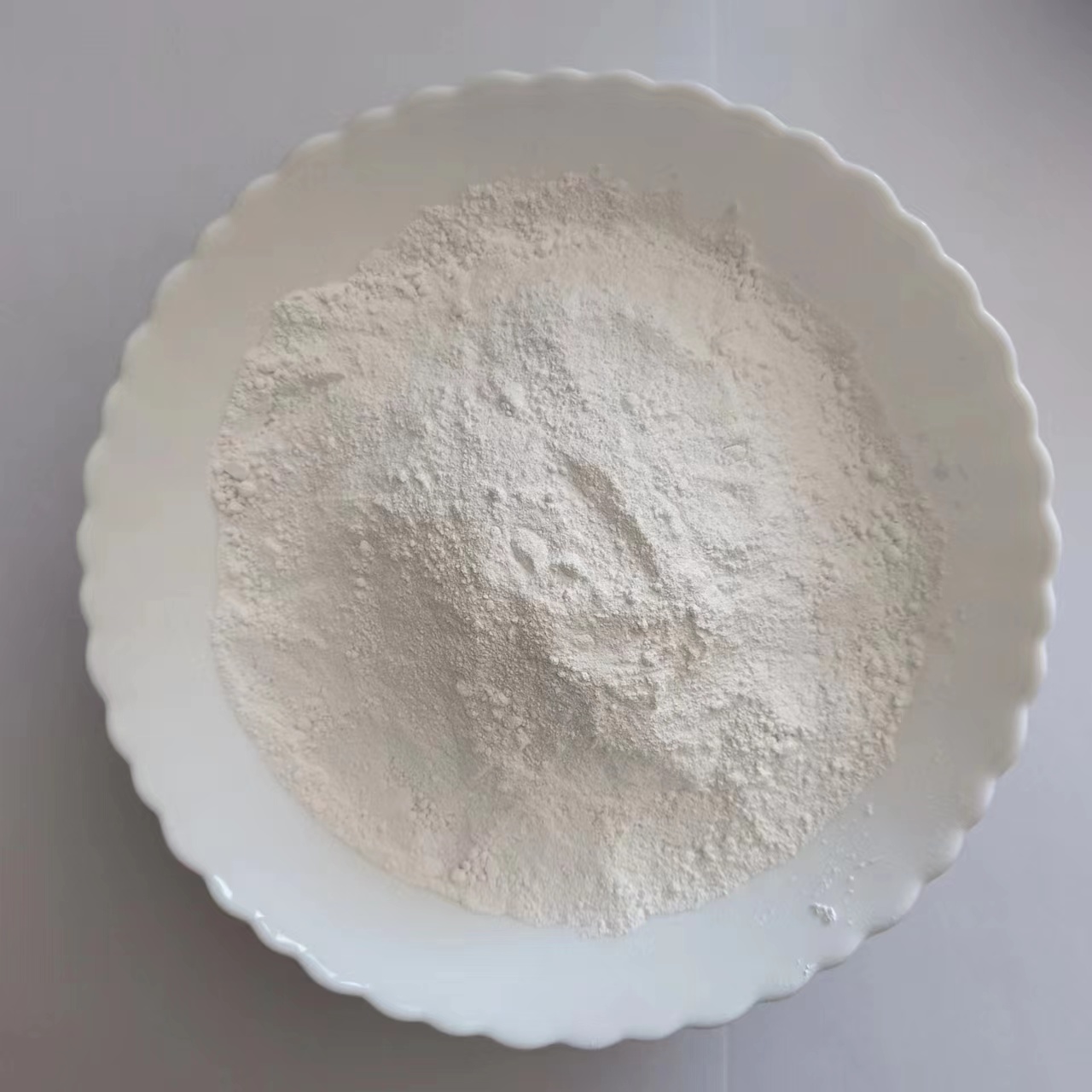

Titanium dioxide (TiO2) is a widely utilized compound known for its exceptional properties, making it indispensable across various industries. Its ability to provide excellent opacity, brightness, and UV resistance has established TiO2 as a key ingredient in products ranging from paints and coatings to plastics, cosmetics, and food items. With the rising demand for TiO2 in different applications, understanding the various wholesale types of TiO2 can aid businesses and consumers in selecting the right product for their needs.

Understanding Wholesale Types of TiO2 A Comprehensive Overview

1. Anatase TiO2 Anatase is less stable than rutile but offers superior photocatalytic properties. This form of TiO2 is often used in applications where UV light absorption and photocatalysis are critical. It is commonly found in outdoor coatings and self-cleaning surfaces due to its ability to break down organic pollutants when exposed to sunlight. The wholesale price of anatase TiO2 can be lower than rutile, making it an appealing option for businesses focusing on cost-effective solutions.

wholesale types of tio2

2. Rutile TiO2 On the other hand, rutile is the more stable and commonly used form of TiO2 in industrial applications. Known for its high refractive index and excellent color retention, rutile TiO2 is extensively used in the production of high-quality pigments for paints, coatings, and plastics. Its superior weather resistance makes it suitable for outdoor applications, ensuring long-lasting performance and durability. The wholesale market typically favors rutile TiO2 due to its superior properties and wider applicability.

The production methods of TiO2 also play a vital role in determining the type. The two primary processes are the sulfate process and the chloride process. The sulfate process generally produces anatase TiO2, while the more efficient chloride process yields high-quality rutile TiO2. Understanding these methods can provide insights into the quality and cost-effectiveness of the TiO2 available in wholesale markets.

In addition to the primary forms, TiO2 can be further modified or treated to enhance specific properties, such as dispersion and compatibility with various matrices. Surface treatments can improve the performance of TiO2 in applications like cosmetics, where it is essential to have a smooth application and skin feel.

In conclusion, when considering wholesale types of TiO2, it is crucial to evaluate the specific requirements of your intended application. By understanding the differences between anatase and rutile TiO2, as well as the implications of production methods and surface treatments, businesses can make informed decisions that align with their operational needs and enhance product performance. As demand for high-quality TiO2 continues to grow, staying informed about these wholesale options will remain vital for industry stakeholders.

-

Lithopone for Plastic & TiO2 R-5568/SK-6658 Masterbatch Solutions

NewsMay.30,2025

-

China Leading Rutile TiO2 Manufacturer - R5566 & R996 Grades Available

NewsMay.30,2025

-

High-Purity Anatase & Rutile TiO2 Powder Trusted Manufacturer

NewsMay.30,2025

-

High-Purity Anatase Products Trusted Supplier & Manufacturer

NewsMay.29,2025

-

Best Price Eco-Friendly Rutile TiO2 Supplier & Wholesale Factory

NewsMay.29,2025

-

Chinese Anatase Titanium Dioxide for Ceramic Glaze Reliable Supplier

NewsMay.29,2025